Nexans | MOBIWAY BOOST

Program Management

User Experience Analysis

Industrial Design

Mechanical Engineering

User performance & Lifecycle Testing

Production Transfer

Intro

—

Pioneering sustainable

practices in construction

Nexans stands at the forefront of the electrical industry as a global supplier of electrical cables, power accessories and electrification solutions that cater for evolving market needs.

In pursuit of innovation, Nexans partnered with Trike to explore a means of making the electrical industry more sustainable. The culmination of this collaboration is the MOBIWAY BOOST, a high-volume, reusable cable spool, born from an immersive user-centered design process and a comprehensive engineering program.

“Trike truly went the extra mile, fully understanding our needs & sharing our passion for design, innovation, & engineering that drives sustainability. The team was proactive, creative, & exceptional at finding solutions, even when they were hard to see.”

Innovation Manager ANZ, Nexans Australia

FRAMING THE CHALLENGE

—

Harmonising user-centred design with engineering excellence

The Nexans MOBIWAY BOOST stands as a model of sustainability, a reusable cable spool that not only reduces waste but also makes the job easier, faster and safer.

The spool is constructed from recyclable materials and seamlessly integrates into an expansive, incentive-driven recycling initiative.

User convenience is paramount, achieved through an innovative self-spooling mechanism that tackles prevalent storage, transportation, and handling challenges. It even provides real-time feedback on cable usage!

research & FOCUS GROUPS

—

Innovation through collaborative design

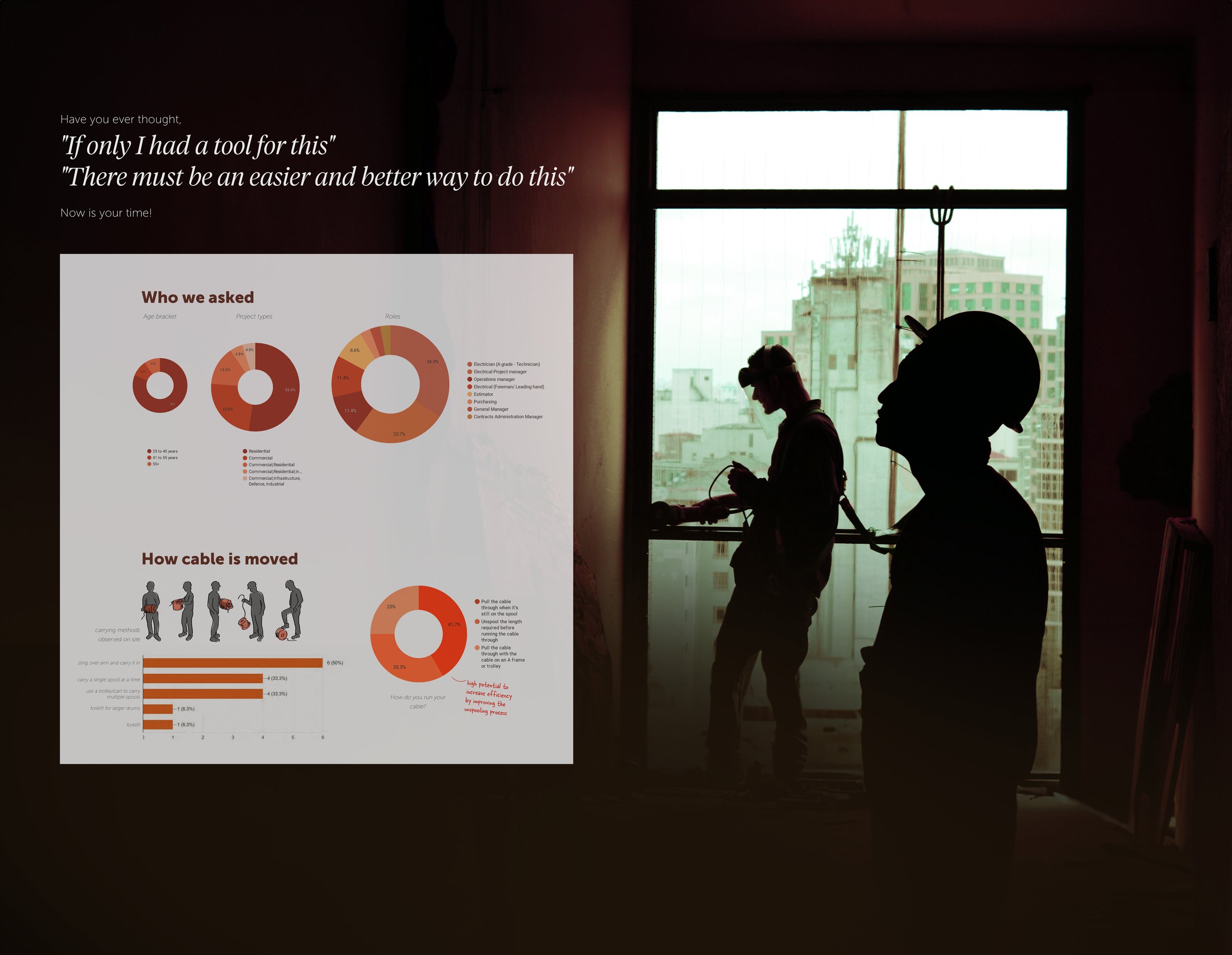

Adopting design thinking methodologies, the team began with an investigative journey into the entire product lifecycle and its extended ecosystem, with a spotlight on pivotal users such as electricians, wholesalers, and the manufacturing plant.

In partnership with Nexans and a number of external focus groups, the research phase was extensive, featuring surveys, in-field observational studies, and the evaluation of initial concepts and prototypes.

prototyping & USER TESTING

—

Rigorous iterative prototyping & testing

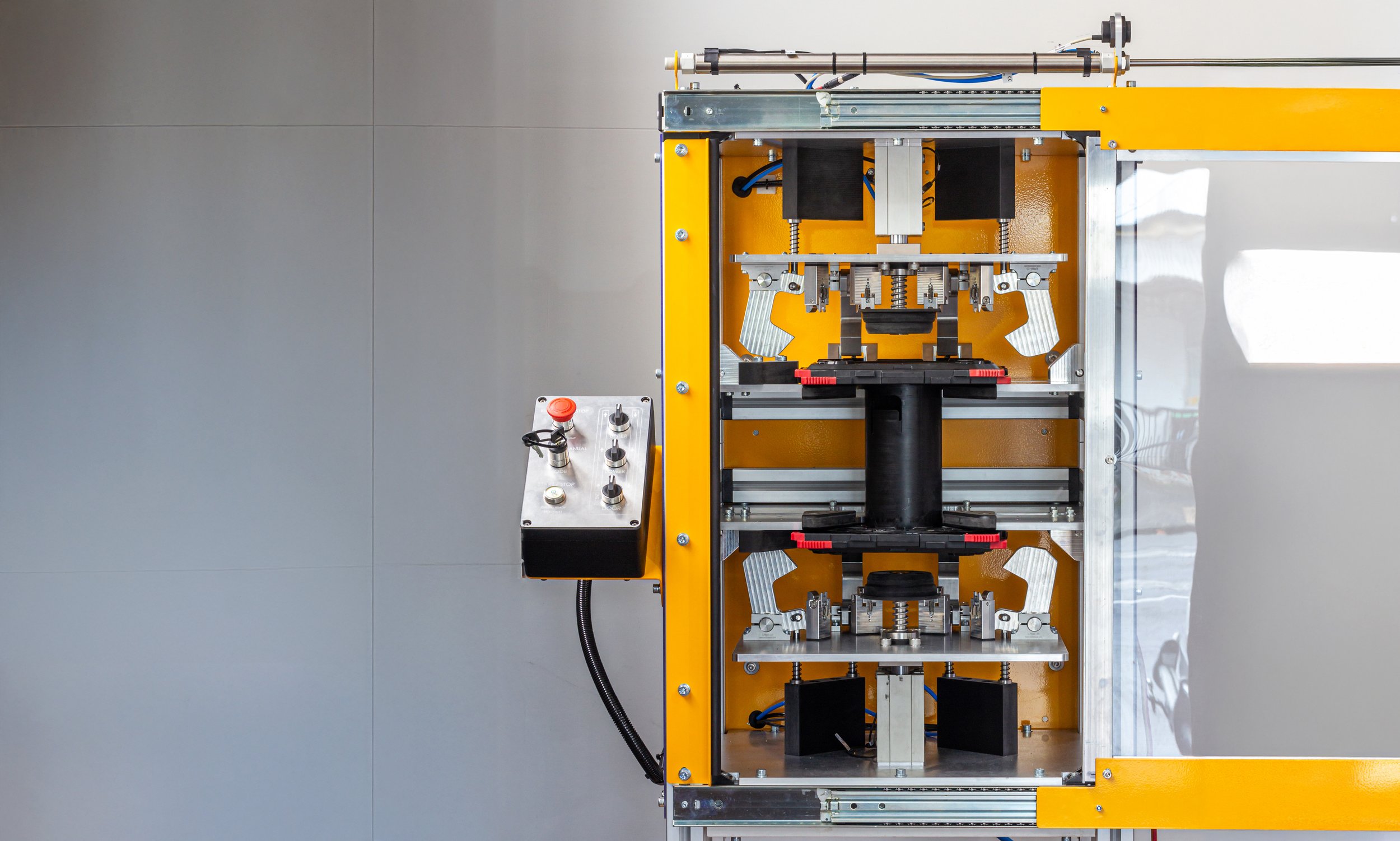

With a clear definition of the problem, the focus shifted to creation. The objective: a reusable spool that delivers tangible value and satisfies the diverse needs within the supply chain.

The design matured through a cycle of iterations, encompassing design refinements, prototype fabrication, and rigorous testing. This included both internal engineering assessments of mechanical concepts and hands-on user testing, fostering a co-creative atmosphere with end-users.

PRODUCtion

—

Navigating the complexities of high-performance production

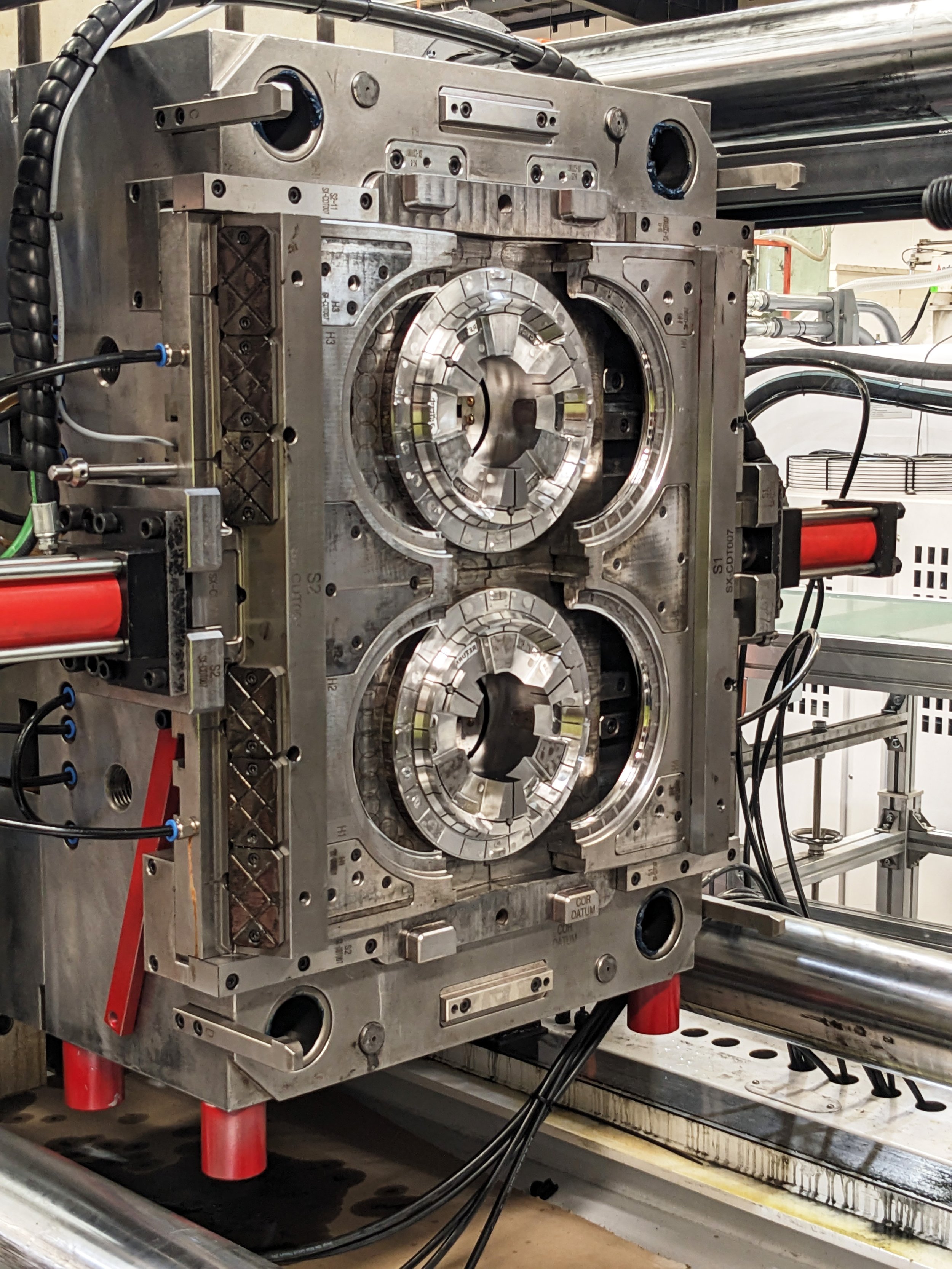

The MOBIWAY BOOST stands out as a unique entity—a high-volume, cost-effective, sustainable product that doesn’t compromise on industrial-grade performance.

The journey through Design For Manufacture (DFM) was intricate, involving exhaustive testing of off-tool samples and meticulous coordination with suppliers.