Cup Pro | Preparation Vessel

Program Management

Industrial Design

Mechanical Engineering

Design for Manufacture

Performance, Lifecycle & User Testing

Production Transfer

INTRO

—

Encouraging reusable

cups on all sides

The environmental impact of single use coffee cups is well known. What is less known is the issues baristas face with customers bringing their own reusable cups into the shop.

Baristas don’t want to handle the customers cups & handling equipment is cumbersome & slow.

Running a busy café themselves, the team at Cup Pro recognised a solution was needed that encouraged reusable cups on both sides of the machine, maintained food safety and hygiene whilst streamlining the artisanal nature of making a quality coffee.

“Our industry needs a universal serving system for reusables. One that seamlessly integrates into the existing operation of every cafe”

Cup Pro Founder

CREATION

—

From by use & ritual

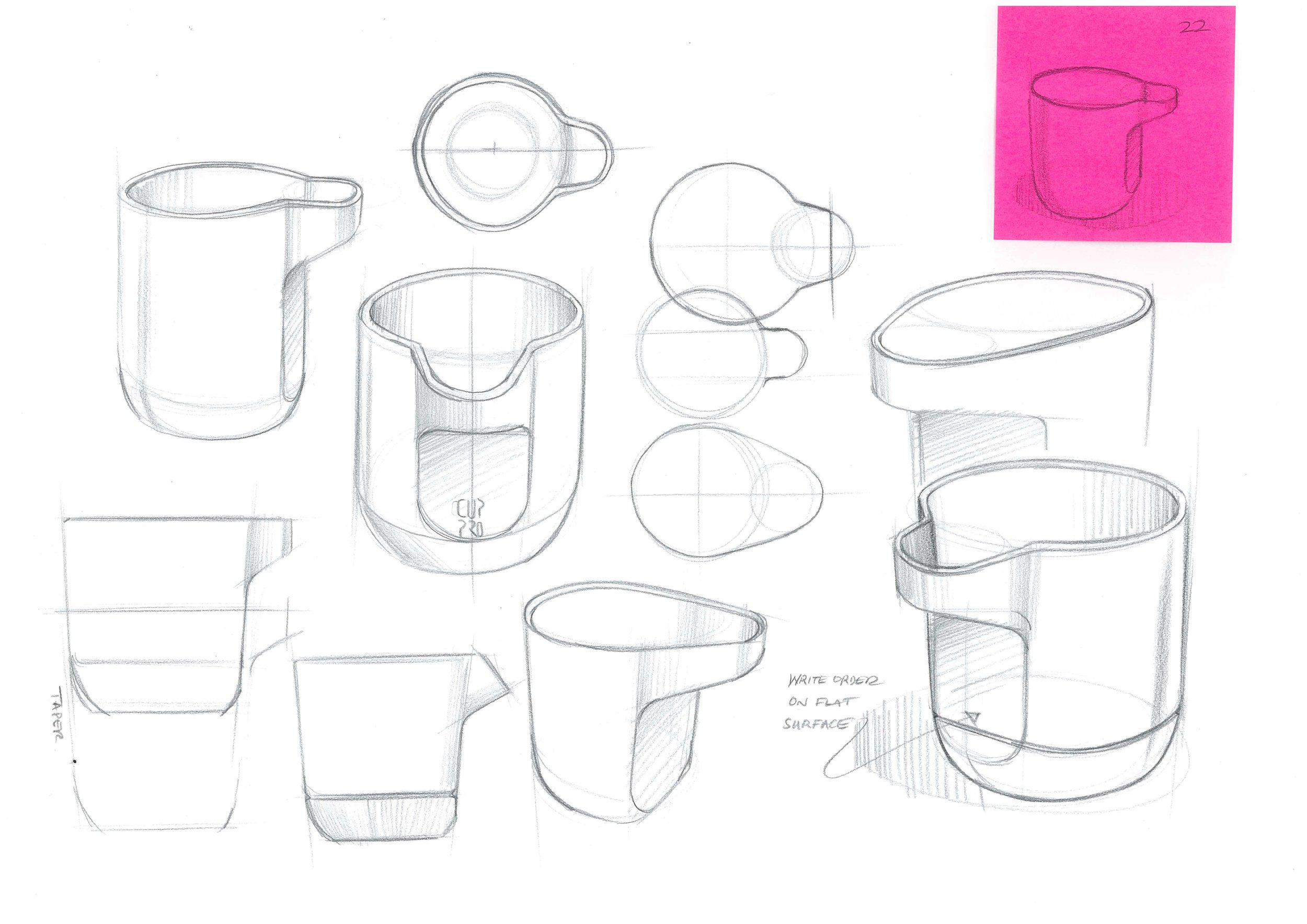

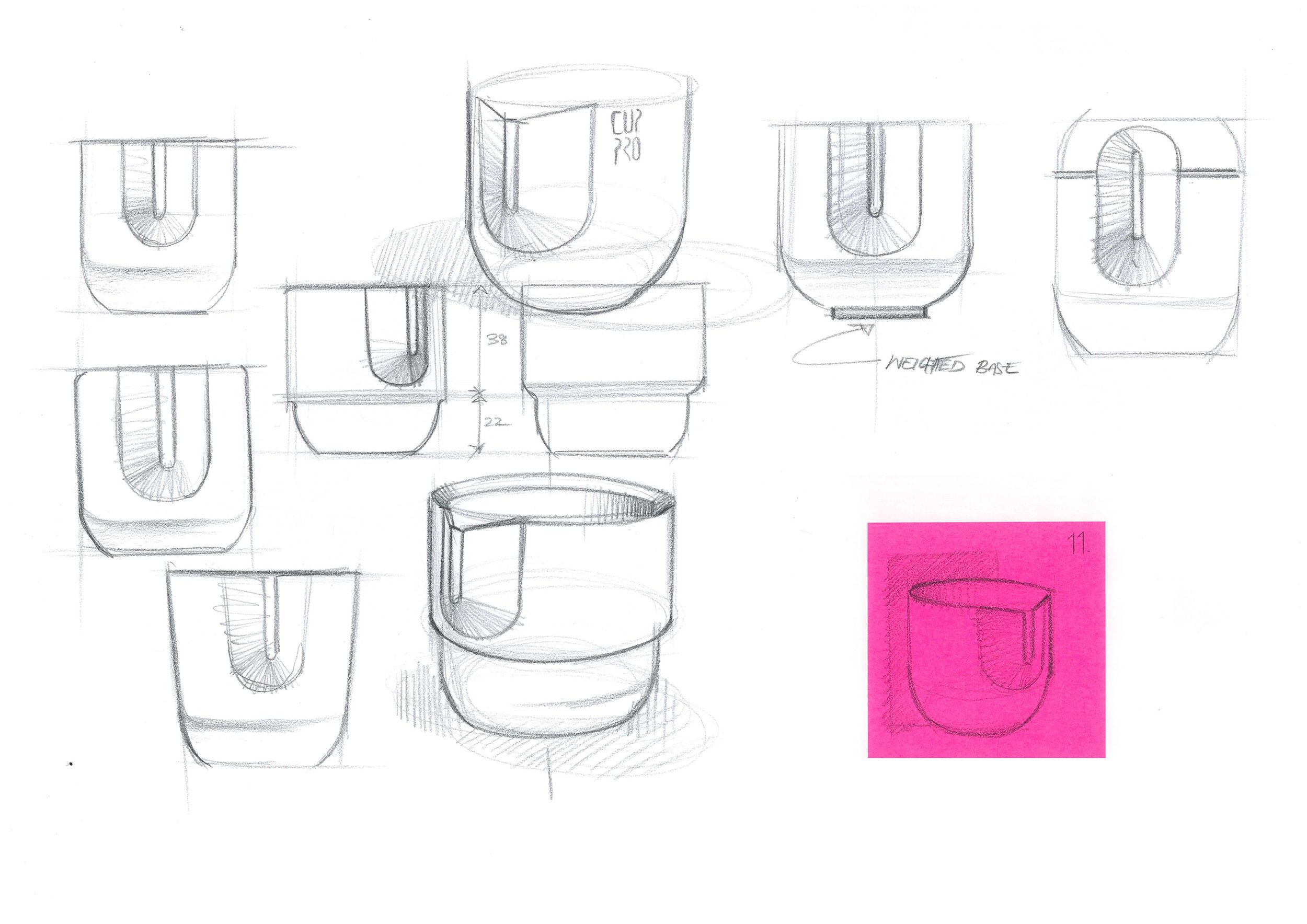

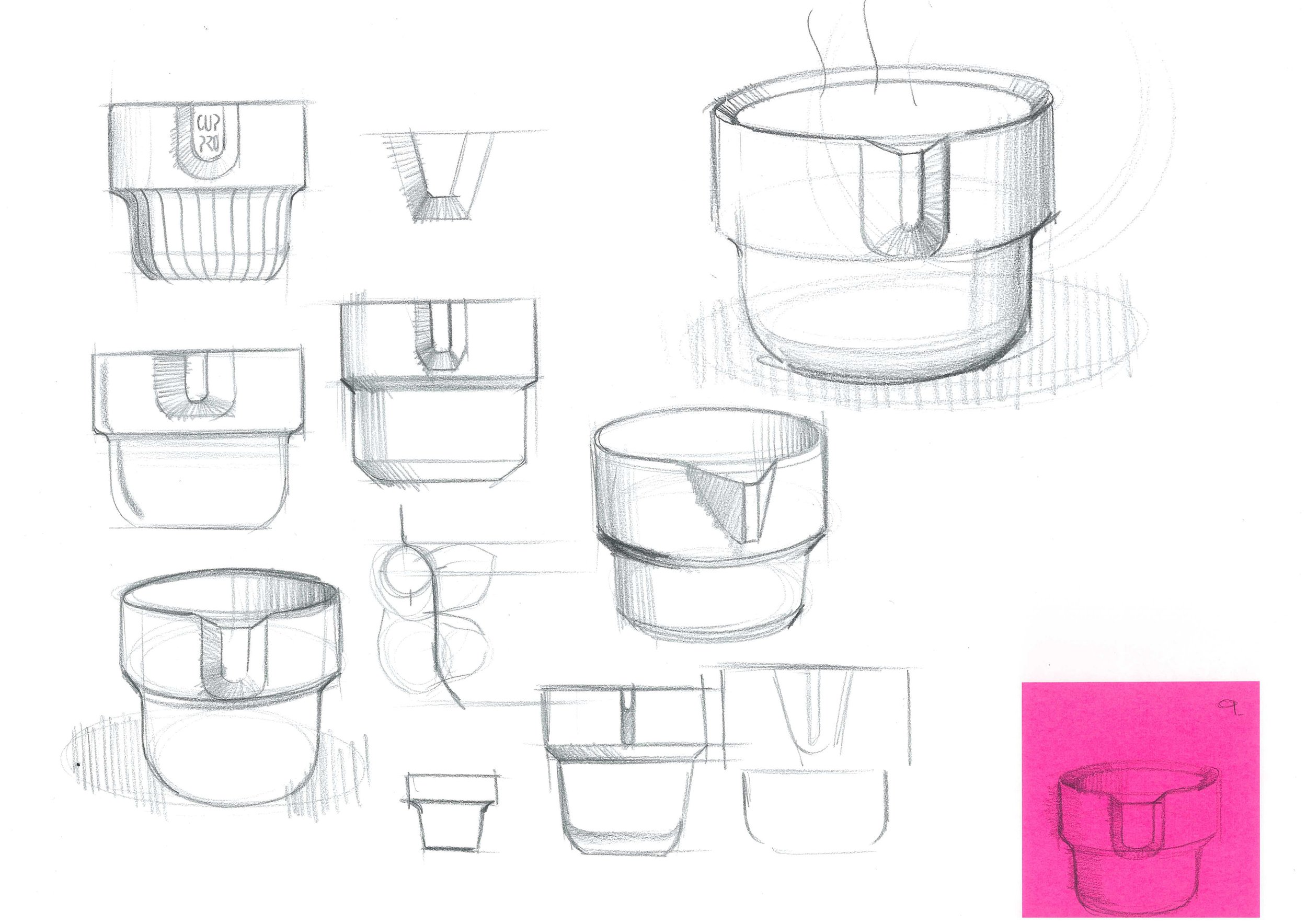

Cup Pro had an idea of a preparation and delivery cup. We worked with their team to help to unpack what the product would need to be. How would it sit with the cafe environment, and how would it benefit the barista?

We mapped the process, user requirements and key touch points. Concept sketches and prototypes allowed the team to rapidly explore ideas on form and function, playing with the pouring ritual, volume, temperature control, cleaning, stacking and customer tagging.

AN AGILE PROGRAM

—

Forged to serve

The design solutions include two alternate stackable cup sizes, optimised for durability in various environments.

The dual-wall construction keeps the coffee warm but provides a cool to touch surface for baristas. The custom spout design enhances the coffee pouring ritual. Internal markers indicate volume, further streamlining the baristas workflow.

And best of all, it makes a damn good coffee.

ENGINEERing

—

Delivering on details

The engineering process encompassed several critical steps. First, thorough thermal analysis guided the adoption of a vacuum-sealed stainless steel dual-wall solution.

Next, the team focused on Design for Manufacturer (DFM) principles, meticulously refining details to enable a vacuum seal of the non-round shape.

Finally, extensive testing validated the cup’s performance, durability, and overall functionality. These combined efforts resulted in a well-engineered beverage preparation vessel that seamlessly aligns with café workflows and elevates the coffee experience